Incorrect packaging setup is one of the most common reasons inventory numbers in SUPY do not match physical stock. This usually happens when the base unit, package quantity, or conversion values are set incorrectly during item creation.

Since SUPY relies on packaging to convert purchases, stock counts, and recipe consumption into a single base unit, any error at this level directly impacts inventory accuracy.

When packaging is configured incorrectly:

GRNs add more or less stock than expected

Stock counts show unrealistic quantities or values

Recipe consumption does not reflect actual usage

Variance increases even when operations are correct

Teams lose confidence in inventory data

The system is functioning correctly — the setup is not.

You may notice:

Receiving 1 case/carton adds an unexpectedly high or low quantity

Stock balances change drastically after counting by pack or case

The same item shows inconsistent quantities depending on the unit used

Repeated variance on the same item every period

Store teams are unsure which unit they should receive or count in

In SUPY:

Every item has one base unit

All inventory movements are converted into this base unit

Packaging defines how much quantity enters inventory

Common causes include:

Selecting the wrong base unit (e.g. piece instead of kg)

Incorrect “quantity in package” values

Multiple packages with inconsistent conversions

Packaging units that do not align with how the item is used in recipes

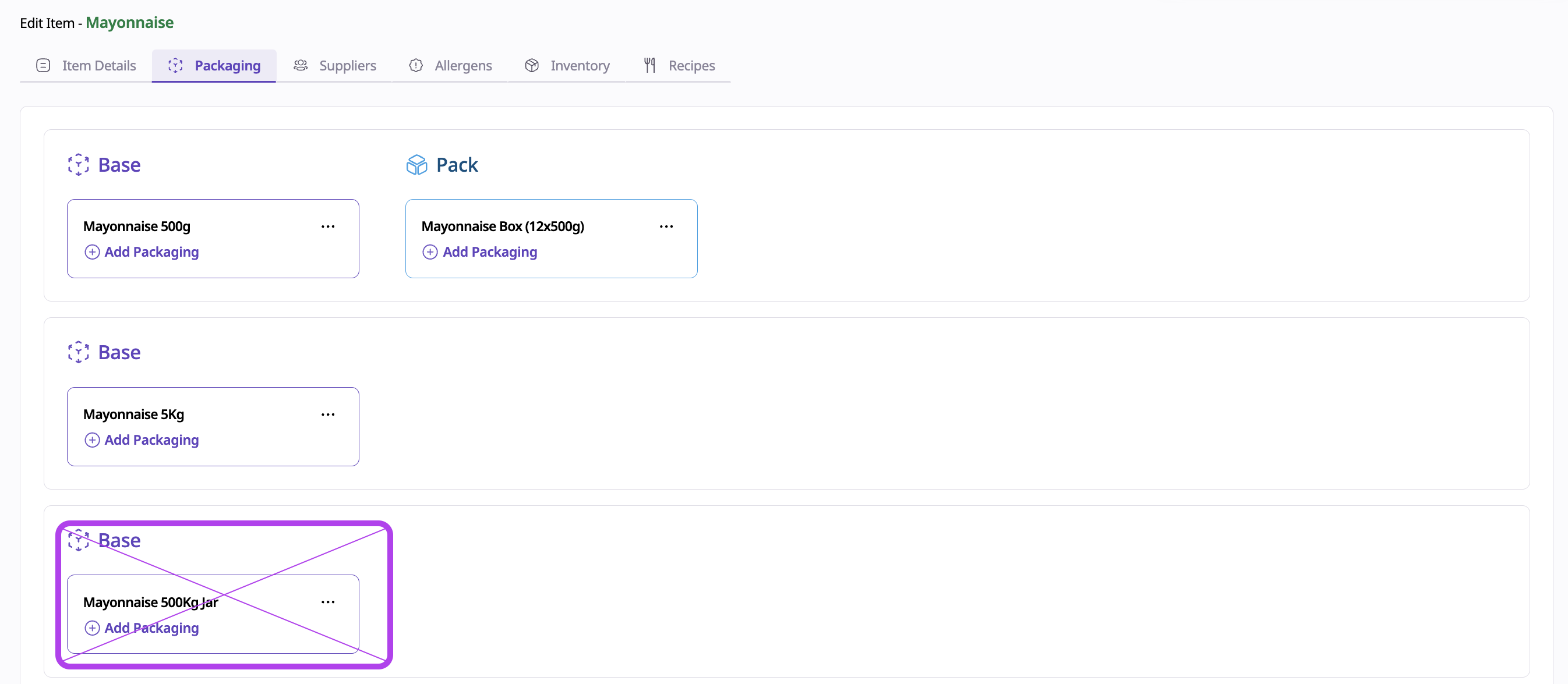

(The packaging of Mayonnaise 500Kg Jar is wrong)

SUPY follows the configuration exactly, so incorrect packaging leads to incorrect inventory results.

Always follow these setup rules:

Define the base unit first

Choose the unit that matches recipe usage (kg, liter, piece)

Create supplier packages based on reality

Use actual supplier invoice quantities

Example: 1 carton = 12 bottles

Example: 1 bottle = 1 kg

Keep packaging simple

Avoid unnecessary unit layers

Use the fewest possible conversions

Align packaging with recipes

Recipes in grams → base unit should be kg

Recipes in pieces → base unit should be piece

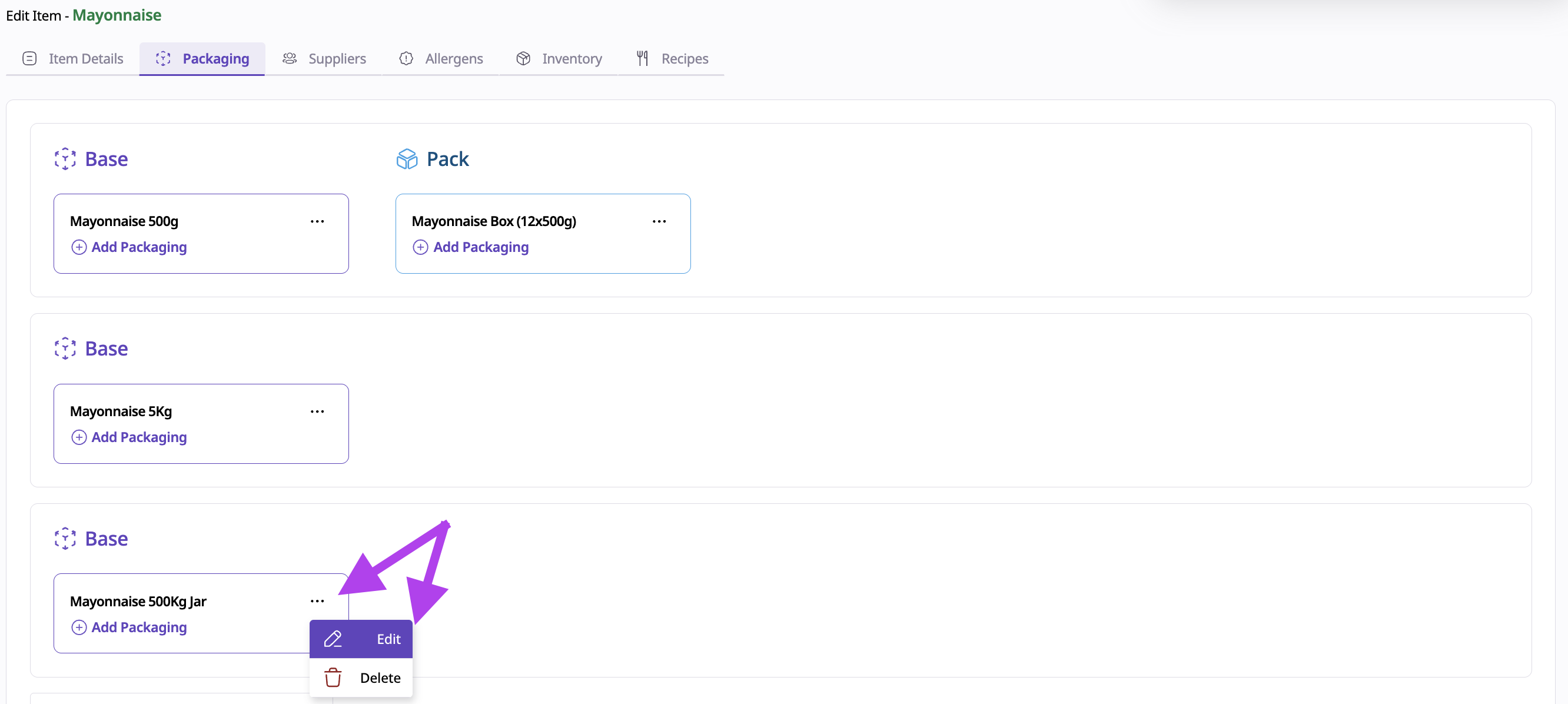

Go to Repository → Items

Open the affected item

Review:

Base unit

All packaging and conversion values

Correct incorrect units or quantities

(Click the three dots to edit the wrong packaging)

Inform store teams of the correct unit to use

Monitor the next GRN and stock count for accuracy

If teams frequently ask:

“Should I count this by box, piece, or kg?”

This usually indicates that packaging is unclear or overcomplicated. Simplifying packaging improves both accuracy and user adoption.

Correct packaging ensures:

Accurate receiving and stock counts

Correct recipe depletion

Reliable COGS and variance reporting

Confidence in inventory data across all locations

Packaging is the foundation of how physical stock is translated into SUPY.

Related Articles